Founder and CEO of Dynamism, Inc., Douglas Krone is one of 10 industry experts selected to serve on the inaugural Editorial Advisory Board of All3DP Pro, the online magazine for the business of 3D printing.

This distinguished group of 10 key additive manufacturing thought leaders, who represent a cross section of the industry, will contribute their expertise and deep knowledge to the growth of the publication’s industry coverage.

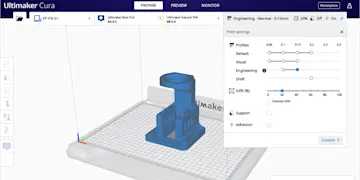

Founded in 1997, Dynamism set out to deliver cutting-edge tech to professionals. In 2012, Dynamism extended that goal by entering the 3D printing industry and becoming the MakerBot’s first official reseller. Since then, Dynamism has grown to become the leading 3D printing solutions provider in the United States with four national showrooms, over 20 best-in-class hardware brands, and countless materials.

Krone says, “It’s humbling to be named a thought leader by All3DP, the 3D printing media platform with the widest global audience of engineers, entrepreneurs, and 3D printing professionals. Our focus will be on 3D printing technologies that are ready to adopt, and to deliver value, now. We’re excited to help organizations move toward Industry 4.0.”

All3DP Pro, launched in early 2020, is the professional and industrial side of All3DP, the world’s most popular online source for 3D printing information with more than 2 million visitors every month. All3DP Pro offers a unique focus on innovation, influencers, and technologies in additive manufacturing (AM).

“These AM industry giants will serve as our sounding board and source, advising us on the most important issues affecting our broad audience of anyone who wants to understand and profit from the business applications of 3D printing,” says Mathias Plica, CEO and co-Founder, All3DP. “They are our eyes and ears out in the field, and they ensure that our content remains cutting-edge, informative, and accurate.”

These 10 industry veterans’ expertise spans deceased in additive manufacturing and covers all the bases, from printers and materials to software and business strategy. As All3DP Pro delves deeper into the business side of 3D printing, editorial board members will serve as stewards of All3DP’s editorial standards — guiding and advising on the most pressing issues and innovations.

Editorial Advisory Board members serve a one-year term, beginning Oct. 1, 2020.